- What is the function of G.I Conduit Pipe ?

GI conduits are generally used for cable and wire systems because of their strong ability to tolerate many twists and bends. Overall, GI conduits improve the ability of cables and wire systems to withstand large amounts of weight and longitudinal stress with little distortion or breakage.

- What’s the difference between cable conduit and cable trunking?

In practice, these two methods of electrical power cable protection and concealment are very similar. However, they each have their own advantages and disadvantages in particular applications.

Conduit is typically the cheaper and more basic approach to wiring protection. It’s widely used wherever smaller cable bundles or individual wires are being run between two terminals, from point A to point B. If they simply need to be protected, tidied up, and/or hidden from view, conduit is often the easiest option.

- What is GI pipe used for electrical conduit?

GI Conduit is a pipe used to protect and route electrical wiring in a building or construction. It provides very good protection to enclosed conductors from impact, moisture, and chemical vapors.

- What are the type of G.I Conduits for Electrical Installations?

Major types are

- ANSI ( American National Standard Institute)/ UL (Under Writers Laboratories)

- BS (British Standard) pipes

- JIS (Japanese Industrial Standard)

- Which are ANSI / UL standard pipes ?

Rigid metal conduit / Rigid Steel Conduit ( RSC) - UL 6 ANSI C80.1

Intermediate metal conduit (IMC) - UL 1242 ANSI C80.6

Electrical metallic tubing (EMT) - UL 797 ANSI C80.3

Flexible metal conduit - UL 1

Liquid-tight flexible metal conduit

- What sizes do ANSI / UL pipes come in?

EMT / IMC – ½ inch to 4’’ RSC – ½ inch to 6 inch

- What are types & sizes of BS pipes ?

BS 4568 Class 4 & Class 3 ( 20mm, 25mm & 32mm)

BS31 Pipes ¾ inch to 2 inch

Flexible Conduit

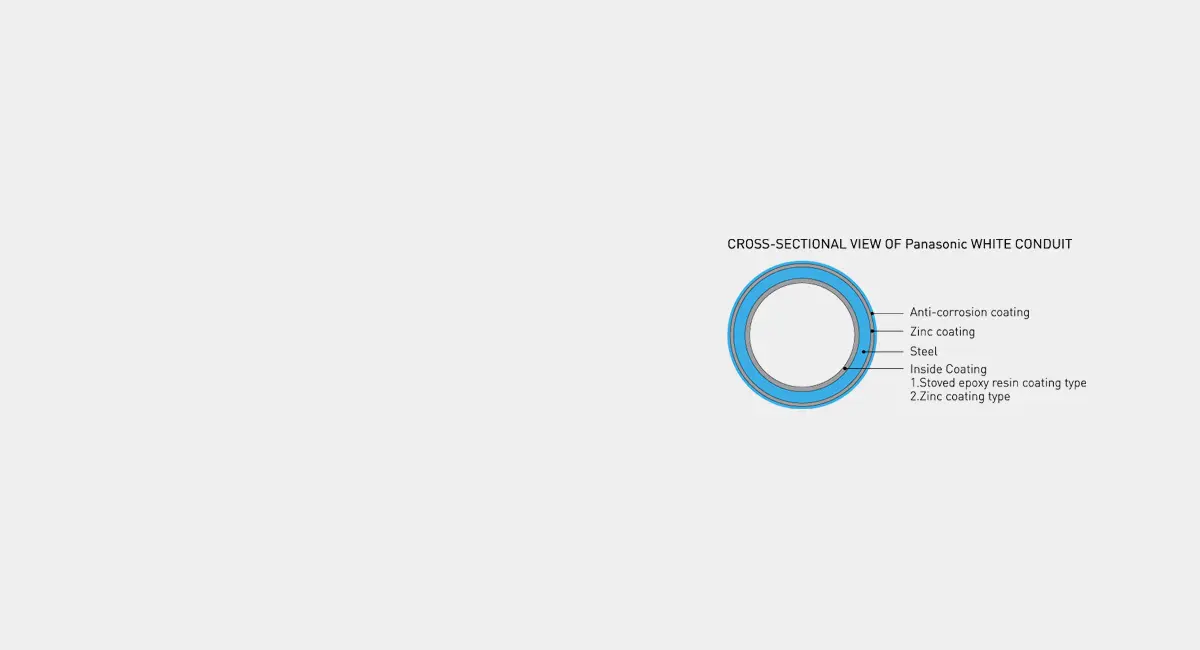

White Conduit Pipes - Flexible Conduit is made of high quality steel and processed by superior galvanizing by in-line hot-dip process for greater protection against corrosion. Finished with durable and clear anti-corrosion coating for higher protection outside and higher grade epoxy coating inside.

Features

1. Easy and Accurate Bending Made of high quality steel and processed by high frequency induction welding to prevent cracking when bent. 2. Easy Wire Pushing and Pulling The high-grade stoved epoxy resin coating on the inside wall makes wire-pulling easy, and protects conduit against corrosion. 3. Easy Coupling and Fast Installation Precise, sharp threads cut by automated machinery ensures fast and easy installation. Precise thread also makes our conduit virtually moisture-tight. 4. High Corrosion Resistance Pure zinc coating on the exterior wall and stoved epoxy resin finish on the inside protects WHITE CONDUIT from corrosion, even by harsh chemicals and sea air. 5. Uniform Quality Flat steel is rolled, zinc-coated and threaded in one continuous automated process for uniform high quality.

Standards

Panasonic WHITE CONDUIT is available in four types conforming to the following standards: - UL/ANSI (EMT, IMC and RSC) - BS (BS31-1940 and BS4568-1970) - JIS (Plain, Thin Wall and Thick Wall)

Series General Specs

| Standard | UL/ANSI/BS |

|---|---|

| Available size | ½ - 4'' |

FAQs

Conduit Pipes

Recently viewed products

Easily access the products you've been looking at on our website. Quickly find the items you were interested in and continue your journey with us.